In Part 05 of our boat building series, watch how we combine advanced materials with an intentional lamination schedule to deliver the strongest, most resilient hulls possible.

The Process

At the core of every Yellowfin is a commitment to using the highest-quality materials available. From the strength imparted by our foam cores to the timely application of gel coat, every detail of a Yellowfin tells a story of dedication to excellence.

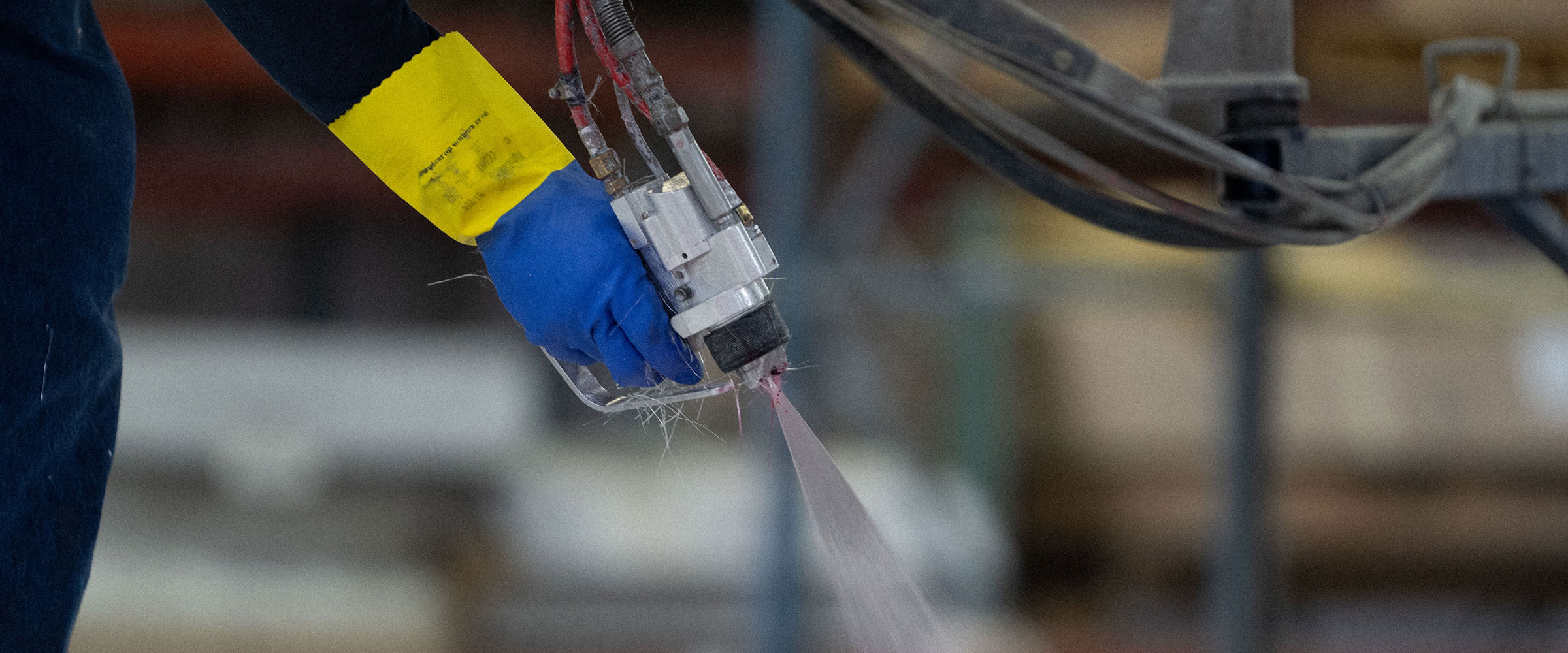

Material selection is deliberate and specific. Each gel coat and skin coat is applied in sequence, building a foundation designed for optimal strength. Our process pushes beyond what is typical in the industry, uniting premium resins and composites to ensure every finished hull is superior in structure and durability.

Key to our approach is Plexus bonding, a method that fuses the three main components of the boat into a single, rigid structure, effectively reducing flex and eliminating structural weak points.

This precise integration of advanced technology and an intentional build schedule establishes a new standard for marine composites. Each step — from the selection of materials to the application of proprietary bonding techniques at the right times — directly impacts the finished vessel’s ability to command rough water environments.

The result is an offshore center console fishing machine built to excel.